If you have to put Mallory into the crank you've definatley done something wrong and it can be expensive as you said.

| Slant Six Forum https://mail.slantsix.org/forum/ |

|

| Gun Drilled Slant 6 Crank https://mail.slantsix.org/forum/viewtopic.php?t=50660 |

Page 1 of 1 |

| Author: | Greg Ondayko [ Fri Dec 28, 2012 8:57 pm ] |

| Post subject: | Gun Drilled Slant 6 Crank |

Hello Folks, Is there any way to gundrill a Stock Production slant 6 crank and have in function correctly? Oril Passages / structural integrity etc. I believe this has been done with some of the custom Billet slant 6 cranks. Also if gundrilling is not an option, what is the best way to lighten a Stock type forged crank? Thanks, Greg |

|

| Author: | CNC-Dude [ Fri Dec 28, 2012 9:59 pm ] |

| Post subject: | |

Greg, i've gundrilled many V8 cranks and quite a few inlines as well. You need some special "long" drill bits and a mill helps too. But it can be done sucessfully. You can also mill some material out from the front and rear of the crank cheeks with a ball mill also, but you will need a V-block fixture to hold the crank along with a large radius ball mill, and again, a mill is gong to be necessary. |

|

| Author: | Turbo Toad [ Fri Dec 28, 2012 11:09 pm ] |

| Post subject: | |

I've thought about having one knife edged for my next build |

|

| Author: | CNC-Dude [ Fri Dec 28, 2012 11:32 pm ] |

| Post subject: | |

I have taken 12 lbs. off of a 292 inline 6 crank by knife-edging, rounding the counterweights up and ball milling the crank cheeks, so it can help in a lot of ways. |

|

| Author: | slantzilla [ Sat Dec 29, 2012 2:05 am ] |

| Post subject: | |

The one issue that has come up lightening Slant cranks is having to put Mallory metal back in to get it to balance. Pretty pricey, and negates most of the weight loss. |

|

| Author: | CNC-Dude [ Sat Dec 29, 2012 7:29 am ] |

| Post subject: | |

If you have to put Mallory into the crank you've definatley done something wrong and it can be expensive as you said. |

|

| Author: | Exner Geek [ Sat Dec 29, 2012 7:38 pm ] |

| Post subject: | |

One of the things I had on my list to make the car lighter that I never got to do was to build an engine around the late model cast crank that weighs about 62#. Guzzi worked on his forged crank with an angle grinder trying to take equal amounts off both sides. He saved considerable weight this way and it obviously worked pretty good. |

|

| Author: | DusterIdiot [ Sat Dec 29, 2012 9:29 pm ] |

| Post subject: | Lol... |

Quote: One of the things I had on my list to make the car lighter that I never got to do was to build an engine around the late model cast crank that weighs about 62#.

I'll let you know how it goes Seymour. I have a block apart, measured and ready to go into the machine shop. Picked a 1979 cast crank block, will use a 1985 cast crank, targetting about the mid-12's in static compression....while it's in their tank and being mag'd I'll have to decide which of 2 cams I have sitting around to use....-D.Idiot |

|

| Author: | emsvitil [ Sat Dec 29, 2012 10:15 pm ] |

| Post subject: | |

If you gun-drill the crank, wouldn't you need to add pipe plugs for the oil passages? |

|

| Author: | CNC-Dude [ Sat Dec 29, 2012 11:17 pm ] |

| Post subject: | |

No, you don't actually drill into the oil holes in the journal. |

|

| Author: | emsvitil [ Sun Dec 30, 2012 12:03 am ] |

| Post subject: | |

Then I'm missing something.... In my mind, I'm envisioning a large drill hole that goes down the center of the whole crank.  This would put holes where there weren't any before (cutting across rod throws) Oil gets to the rod throws via passages from the main bearings. Wouldn't the gun-drill hit these passages? |

|

| Author: | CNC-Dude [ Sun Dec 30, 2012 10:17 am ] |

| Post subject: | |

Aftermarket cranks have their oil holes purposely repositioned as to not be affected by the gun drilling of the rods or mains. Drilling a crank that originally wasn't intended by the factory to be drilled by them or anyone else takes some strategy and planning to not drill into the existing oil holes and ruining the crank. Also you mentioned the drilling being in the center of the rod throw, and that isn't always where you can drill the holes, it depends on where the placement of the oil holes are that will determine where you can safely drill. Sometimes, on the second or third rod pin, you even have to drill at an angle to clear counterweights and/or get the best positioning possible. Its really not for the novice to attempt. You also have to make sure you don't drill too close to the edge of the journal as well, usually a 5/8" drill is a good safe starting point, but sometimes, depending on the crank design, you can sneak a larger one in to get more material out. Its also an "all" or "nothing" job, if you can't drill all 6 of the journals, then you shouldn't drill any of them, as this will greatly affect how the crank can be balanced if you only drill 2 or 3 of the journals and not all of them. Thats when ball milling the front and rear of each rod pin may be a better choice at weight removal, since you can get to all of them easily with a V-block fixture. |

|

| Author: | CNC-Dude [ Mon Dec 31, 2012 9:45 am ] |

| Post subject: | |

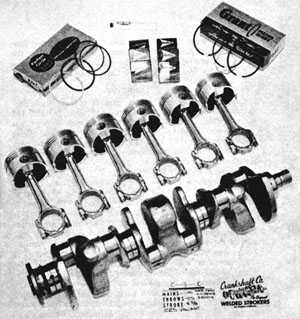

Here are a few pics showing the before and after of the first steps of crank lightening. Stock Crank Cheeks:  Ball Milled Crank Cheeks:This is done to the front and rear of each journal. Good time to knife-edge while its in the fixture!

|

|

| Page 1 of 1 | All times are UTC-08:00 |

| Powered by phpBB® Forum Software © phpBB Limited https://www.phpbb.com/ |

|